Sun, Style & Stain Resistance: Your Guide to Outdoor Fabric

When it comes to selecting outdoor fabric, beauty is only part of the equation. Behind every stylish pattern or vibrant hue lies a world of performance specifications that can make or break your project—especially in high-exposure environments. From UV resistance to water repellency, understanding the terminology and technical features of outdoor textiles is key to making informed, professional choices. This blog breaks down the most important specs and finishes so you can confidently specify outdoor fabrics that look great and perform even better.

Solution Dyed Acrylic

Most fabrics begin with fibers that are initially colorless. The fibers are woven into yarns and the yarns are then dyed and woven into fabric. With solution dyed acrylic the coloring takes place before the yarn is ever created. A liquid acrylic solution is mixed with color and formed into a fiber. The fiber never existed without color. The fiber is then spun into a yarn that is already permeated with color. The final result is a fabric that will remain colorfast after sun exposure, wear and tear and even bleach application. It is soft, comfortable and breathable. It is water resistant and quick drying. It is not water-proof. Acrylic does not promote the growth of fungus or mildew; however mildew may grow on soils or spills that are not removed promptly from the fabric. As durable as acrylic is it should be treated as a synthetic. Do not dry clean. There should be no need to tumble dry since it will air dry quickly. Ironing is not needed. However, if you should find it necessary use the synthetic setting. Solution dyed acrylic fabrics are often as stylish as indoor products, and work equally as well, if not better because of their ease in cleaning. Solution dyed acrylic fabrics will rate up to 2200 hours of U.V. protection from fading. Think of solution dyed acrylic yarn as a carrot. When cut the color goes all the way through the yarn.

Printed Acrylic/Polyester

The most decorative of the outdoor fabrics is also the most affordable. Acrylic is used as a base cloth for many reasons. Because of its strength, durability, resilience, resistance to wrinkling, shrinking, fading, mildew and fungus it is a great choice. In addition it dries quickly and is UV resistant. Polyester has many of the same qualities. It is strong, resistant to stretching and shrinking, resistant to chemical damage, quick drying, wrinkle resistant and is crisp and resilient when wet or dry. Both maintain printed patterns well and resist rot from outdoor elements. The polyester or acrylic base cloths are screen printed with dyes that are resistant to fading and outdoor elements. In addition, a water repellant guard is factory applied in the final finishing process to further protect the pattern. Fibers are synthetic and should be treated as such. Do not dry clean or tumble dry as it can break down the protective finish. Filament polyester and acrylic is woven of continuous fibers and often have a “slick” feeling hand. Most of these type fabrics can’t be cleaned with bleach as with solution dyed acrylics can. The average fabric in this category will rate only about 300 hours of U.V. protection from fading. These products are thought of as seasonal, however, with proper care they can last for an extended period. Think of printed polyester/printed acrylic products as a radish. The color is vibrant on the exterior, but only sits on the top of the fabric and does not permeate to the core of the yarn.

Lightfastness & Colorfastness

You may have heard the terms “lightfastness” or “colorfastness to light” when shopping for the perfect outdoor fabric. Maybe you have seen a lightfastness rating or a particular number of light hours listed on a fabric’s specs, but maybe you didn’t know what they meant or fully understood their significance. Lightfastness or Colorfastness to light is, “the degree to which a dye resists fading due to constant light exposure. Although this may be particularly important when shopping for fabric that will be used in a sunroom or outdoors, it is important to note that all dyes have some susceptibility to light damage. Problems with fading tend to occur when the fabric chosen was not produced to meet the end use, like using a basic multi-purpose cotton print on patio furniture.

Most fabric manufacturers complete UV tests that provide consumers with a rating that directly correlates with the fabric’s ability to resist fading or its lightfastness. The most commonly used method in the United States is the American Standard AATCC 169.3. With this test the fabric is exposed under specific conditions to a controlled light source which simulates the sun spectrum of Albuquerque, New Mexico. At timed intervals, the test swatch is compared visually to a gray scale and the degree of fading is rated on a scale from 1 to 8.

| Degree of Fading | Light Fastness Type | |

| 8 | No fading | Outstanding |

| 7 | Very slight fading | Excellent (over 100 years) |

| 6 | Slight fading | Very good (50-100 years) |

| 5 | Moderate fading | Good (25-50 years) |

| 4 | Appreciable fading | Moderate (25-50 years) |

| 3 | Significant fading | Fair (15-50 years) |

| 2 | Extensive fading | Poor (2-15 years) |

| 1 | Very extensive fading | Very poor (less than 2 years) |

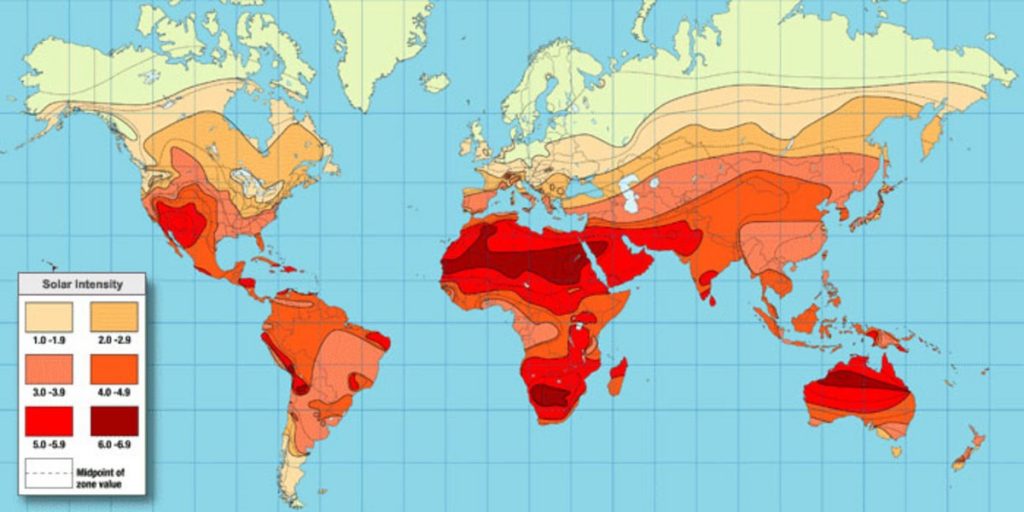

Manufacturers may also provide a lightfastness in number of sunlight hours. Any number of hours could be given, but outdoor fabrics usually rate anywhere from 500-2000+. The exact number of hours or years a fabric will last without fading is impossible to determine as there are many factors that come into play, such as the type of dye used, fiber content of the fabric, sun intensity and geographical location. Take a moment to consider the difference of the sun’s intensity in New York compared to that of New Mexico. Other factors that may affect lightfastness include temperature, humidity, and airflow.

Most fabric manufacturers complete UV tests that provide consumers with a rating that directly correlates with the fabric’s ability to resist fading or its lightfastness. The most commonly used method in the United States is the American Standard AATCC 169.3. With this test the fabric is exposed under specific conditions to a controlled light source which simulates the sun spectrum of Albuquerque, New Mexico. At timed intervals, the test swatch is compared visually to a gray scale and the degree of fading is rated on a scale from 1 to 8.

General Care & Cleaning

The care and cleaning of outdoor performance fabrics are about the same. Most fabrics may be maintained, and simple stains removed, by following three easy steps.

- Lightly brush off any excess debris.

- Prepare a cleaning solution of 1/4 cup mild soap per gallon of warm water. Spray fabric with solution and use a sponge or soft bristle brush to clean making sure that the fabric is completely soaked through.

- Rinse thoroughly with clean water and allow fabric to air dry.

Outdoor fabrics do not stain easily or mildew. However mildew may grow on foreign substances not readily removed from the fabric. If mildew or staining occurs please follow the instructions below.

- Prepare a cleaning solution of 1 cup bleach and 1/4 cup mild soap per one gallon of water.

- Soak the entire trouble spot with the cleaning solution and scrub with a sponge or soft bristle brush until the stain is removed. Apply more solution as necessary.

- Rinse thoroughly with clean water and allow fabric to air dry.

- If the problem area is severe the amount of bleach in the solution may be increased as needed.

- DO NOT DRY CLEAN.

- DO NOT STEAM.

RM COCO offers a number of outdoor/performance trimmings in its product offering. These items are made of solution-dyed acrylic yarns and may be maintained using the same general cleaning instructions as our outdoor/performance fabrics.

Sunbrella® Care & Cleaning

Sunbrella® products come with their own specific cleaning instructions. These products may be maintained as listed below.

All Sunbrella® fabrics are made of durable, all-weather solution dyed acrylic. Products can be machine washed in cold water and line dried or professionally dry cleaned. Most stains on Sunbrella® fabrics can be cleaned up with a mild soap and water solution.

- Spot wash with a solution of natural soap and lukewarm water.

- Rinse thoroughly with clean water to remove soap and air dry.

- For stubborn stains, use fabric spot remover. Follow the directions on the container.

- Sunbrella® acrylic does not promote mildew growth. However mildew may grow on foreign substances not readily removed from the fabric. To clean mildew stains prepare a mild solution of one cup bleach and two capfuls of natural soap per gallon of water. Spray on entire area and allow to soak in. Sponge thoroughly with clean water and air dry.

Machine washing of Sunbrella® products

- Pre-treat any heavily stained areas with an appropriate stain remover.

- Depending on wash load size, use normal amounts of mild laundry soap.

- Machine wash in cold water for best results.

- Air dry.

Sign Out

Sign Out

View Cart

View Cart